Home > Products > Blow Molding Machine > 10L 15L 20L 25L 30L Automatic Extrusion Plastic HDPE Bottle, Jerry Can, Drum Canister Making Blowing Blow Moulding/Molding Machine

10L 15L 20L 25L 30L Automatic Extrusion Plastic HDPE Bottle, Jerry Can, Drum Canister Making Blowing Blow Moulding/Molding Machine

PXB100DB 20L-30L Double Station Blow Molding Machine- Fixed Opening-Closing Clamping with 5L Accumulator Head Capacity- Perfect Usage for production of Big toys, auto parts, Jerry Can, sprayer and so on.- Hydraulic Servo System control with quick action speed. - High capacity amount with energy savi......

Send Inquiry

Product Description

PXB100DB

20L-30L Double Station Blow Molding Machine

- Fixed Opening-Closing Clamping with 5L Accumulator Head Capacity

- Perfect Usage for production of Big toys, auto parts, Jerry Can, sprayer and so on.

- Hydraulic Servo System control with quick action speed.

- High capacity amount with energy saving.

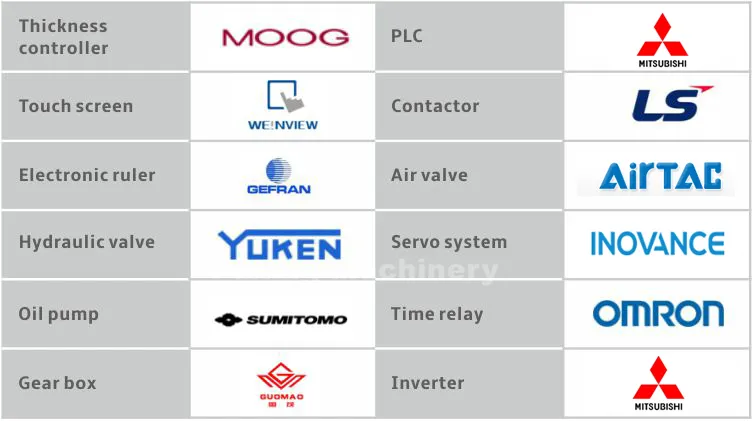

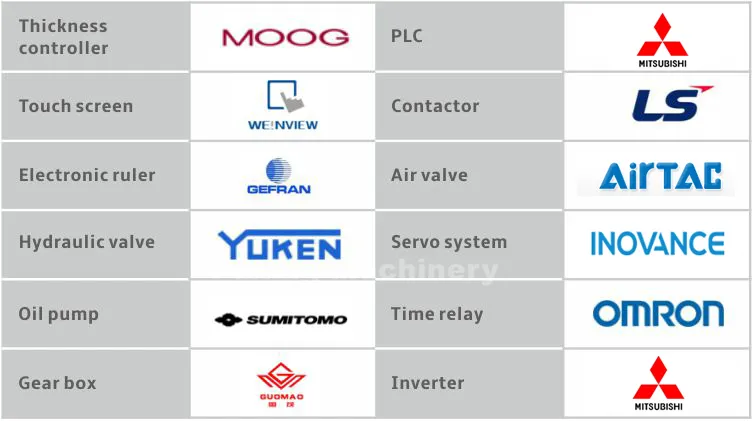

Configuration List

Parameters:

Delivery Time:

- No later than 60 days after receipt of the deposit

Training:

- We provide training service for two or three operating men for free (but the cost for trainer's board and lodging is not included).

Installation:

- The supplier will send one specialist to test run the machine until it is running in normal state.

Guarantee:

- Our guarantee is valid for a period of 12 months. If the malfunction caused of the machine's self quality, we will troubleshoot it for free.

Auxiliary Equipments:

- Auxiliary equipments and moulds for production line are available and optional, please kindly ask for quotation.

OUR FACTORY:

20L-30L Double Station Blow Molding Machine

- Fixed Opening-Closing Clamping with 5L Accumulator Head Capacity

- Perfect Usage for production of Big toys, auto parts, Jerry Can, sprayer and so on.

- Hydraulic Servo System control with quick action speed.

- High capacity amount with energy saving.

Configuration List

| PLC | MITSUBISHI | Japan |

| Touch Screen | HITECH | Taiwan |

| Inverter | MITSUBISHI | Japan |

| Power Supply | MEAN WELL | Taiwan |

| Relay | OMRON | Japan |

| Hydraulic Valves | YUKEN | Japan |

| Hydraulic Pump | YUKEN | Japan |

| Contactors | LS(LG) | Korea |

| Solid relay | FOTEK | Japan |

| Breaker | LS(LG) | Korea |

| Temperature Control Module | MITSUBISHI | Japan |

| Oil Sealing | DZ | Taiwan |

| Oil Tube | LIEBAO | Taiwan |

| Transducer | GEFRAN | Italy |

| Proximity Switch | SONON | China |

| Motor | SIEMENS | China |

| Air Valve | FESTO | Germany |

| Parison Controller | Moog | Japan |

| Servo Valve | Moog | Japan |

Parameters:

| Material | PE,PP,ABS... | |

| Max container capacity | L | 30 |

| Output(dry cycle) | pc/hr | 650×2 |

| Machine dimension(L×W×H) | M | 6.4×6.2×4 |

| Machine weight | T | 23 |

| Clamping Unit | ||

| Clamping force | kn | 200 |

| Mold platen size(W×H) | mm | 830×800 |

| Platen opening stroke | mm | 350-850 |

| Platen moving stroke | mm | 500 |

| Max mold size(W×H) | mm | 590×700 |

| Mold thickness | mm | 360-420 |

| Power | ||

| Servo oil pump motor power | KW | 13 |

| Servo pump displacement | L/MIN | 80 |

| Blow pressure | MPA | 0.8 |

| Air consumption | M3/MIN | 0.7 |

| Cooling water pressure | mpa | 0.3 |

| Water consumption | L/min | 70 |

| Average energy consumption | KW | 52-60 |

| Extruder unit | ||

| Screw diameter | mm | 100 |

| Screw L/D ratio | L/D | 24 |

| HDPE Melting capacit for HDPE | kg/hr | 160 |

| Number of heating zone | zone | 5 |

| Screw heating power | kw | 28 |

| Screw fan power | KW | 0.5 |

| Extruder motor power | kw | 55 |

| Die head | ||

| Number of heating zone for single die head | zone | 4 |

| Heating power for single die head | kw | 19 |

| Max die-pin diameter | mm | 250 |

| Accumulator capacity | L | 5 |

| (HDPE) Accumulator weight(HDPE) | KG | 3.75 |

Delivery Time:

- No later than 60 days after receipt of the deposit

Training:

- We provide training service for two or three operating men for free (but the cost for trainer's board and lodging is not included).

Installation:

- The supplier will send one specialist to test run the machine until it is running in normal state.

Guarantee:

- Our guarantee is valid for a period of 12 months. If the malfunction caused of the machine's self quality, we will troubleshoot it for free.

Auxiliary Equipments:

- Auxiliary equipments and moulds for production line are available and optional, please kindly ask for quotation.

OUR FACTORY:

Related Category

Plastic Machinery

Woodworking Machinery

Blow Molding Machine

Plastic Recycling Machine

Injection Molding Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.