160~220L Plastic Barrel/Tank Blow Molding Machine

Extrusion Blow Molding MachineModel: HC seriesThe blow molding machine model HC series can produce bottle, kettle, can, bucket etc. The machine is especially designed for producing with material such as PE, PP etc.Basic installation includingDie head: Accumulator die head Extrusion system: Adopt imp......

Send Inquiry

Product Description

Extrusion Blow Molding Machine

Model: HC series

The blow molding machine model HC series can produce bottle, kettle, can, bucket etc. The machine is especially designed for producing with material such as PE, PP etc.

Basic installation including

- Die head: Accumulator die head

- Extrusion system: Adopt imported automatic temperature controlling device. Drive the screw with motor reducer to realize stepless regulating

- Clamping device: Adopt bi-directional synchronous clamping device with double axis single cylinder.

- Blowing device: with bottom blowing type (optional)

- Hydraulic system: The whole hydraulic system adopts imported servo motor energy-saving system which can save almost 40% power consumption.

- Electric controlling system: Adopt Panasonic brand PLC or B&R brand PCC. Every electric component is in famous brand.

Technical data and parts instructions of blow molding machine for series of HC (the specification is only for your reference)

| HC75E | HC90E | HC100E | HC120E | |

| Max. volume of products(L) | 25(30) | 50(60) | 120(160) | 230(260) |

| Screw diameter(mm) | φ75 | φ90 | φ100 | φ120 |

| L/D | 25:1 | 25:1 | 25:1 | 28:1(30:1) |

| Plasticizing capacity(kg/h) | 100 | 150 | 180(220) | 270 |

| Platen dimension(W×H)(mm) | 750×650 | 900×800 | 1050×1000 | 1400×1600 |

| Platen opening stroke (mm) | 250~800 | 450~1100 | 550~1400 | 800~1800 |

| Clamping force(KN) | 270 | 300 | 550 | 750 |

| Accumulator volume(L) | 4.2 | 6(8) | 12(16) | 20(25) |

| Max diameter of die(mm) | 250 | 350 | 400 | 350 |

| Blow pin up and down stroke(mm) | 150 | 150 | 150 | 150 |

| Expand stroke(mm) | 140~300 | 140~420 | 140~550 | 140~600 |

| Bottom blow pin up and down stroke(mm) | 250 | 250 | 250 | 250 |

| Platform up and down stroke(mm) | 350 | 400 | 450 | 450 |

| Cooling water pressure(Mpa) | 0.3 | 0.3 | 0.3 | 0.3 |

| Air pressure(Mpa) | 0.8 | 0.8 | 0.8 | 0.8 |

| Hydraulic system pressure(Mpa) | 16 | 16 | 16 | 16 |

| Die head heating power(kW) | 18 | 20 | 25 | 40 |

| Extrusion heating power(kW) | 18 | 25 | 30 | 47 |

| Oil pump motor power(kW) | 11 | 11 | 15 | 2x15 |

| Extrusion motor power(kW) | 30 | 45 | 55(75) | 110(132) |

| Total power(kW) | 81 | 105 | 129(149) | 238(260) |

| Average consumption(kW/h) | 28 | 40 | 50(58) | 113(125) |

| Machine weight(T) | 11 | 14 | 17 | 30 |

| Machine dimension(LxWxH)m | 4.5 x2.5x3.8 | 5.2x2.9x4.6 | 5.85x3.1x4.8 | 8.5x4x6 |

Components (can be adjusted)

| Item | Technology content |

| 1.Hydraulic system | Servo oil pump: B&R (Austria) Hydraulic valve: YUKEN (Japan) Proportion valve: HNC (Taiwan) Servo valve: ATOS (Italy) Oil-way pressure control: Proportion pressure control Seal element: NOK (Japan) |

| 2. Electric control | Transducer: SCHNEIDER (France) PCC: B&R (Austria) Contactor: SCHNEIDER (France) Relay: OMRON (Japan) Proximity switch: SCHNEIDER (France) Electric ruler: NOVOTECH / GEFRAN(ITALY) Light curtain senor: Sensorc (China) Thickness servo control: B&R (Austria) Air switch: Meilan (China) Solid-state relay: CRYDOM (USA) |

| 3. Clamping unit | Form:hydraulic clamping directly, Two-way synchronization institutions Drive form:differential motion quick Clamping, Two-rod structure g, Content model in a large space. |

| 4. Die head | Die structure: Accumulator type Runner form: First in first out Material of main runner part: 38CrMoAlA;42CrMo |

| 5.Extrution system | Drive form: Frequency Speed reducer: Alloy steel gearbox Material of barrel and screw: 38CrMoAlA Heating: Casting-aluminum heating device Cooling fan: Huanqiu |

| 6.Pneumatic system | Main air valve: FESTO (Germany) |

| 7.Clamp unit | Air cylinder: FESTO (Germany) |

| 8.Motor | Siemens Beide (China) |

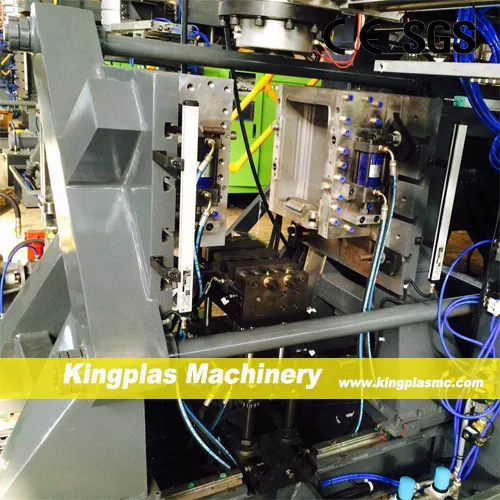

Photo

If you need more information of the machine, please kindly send an email to us. We aslo warmly welcome you to visit our factory. Hope to build long term business relationship with you in the near future!

Related Category

Plastic Machinery

Woodworking Machinery

Blow Molding Machine

Plastic Recycling Machine

Injection Molding Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.