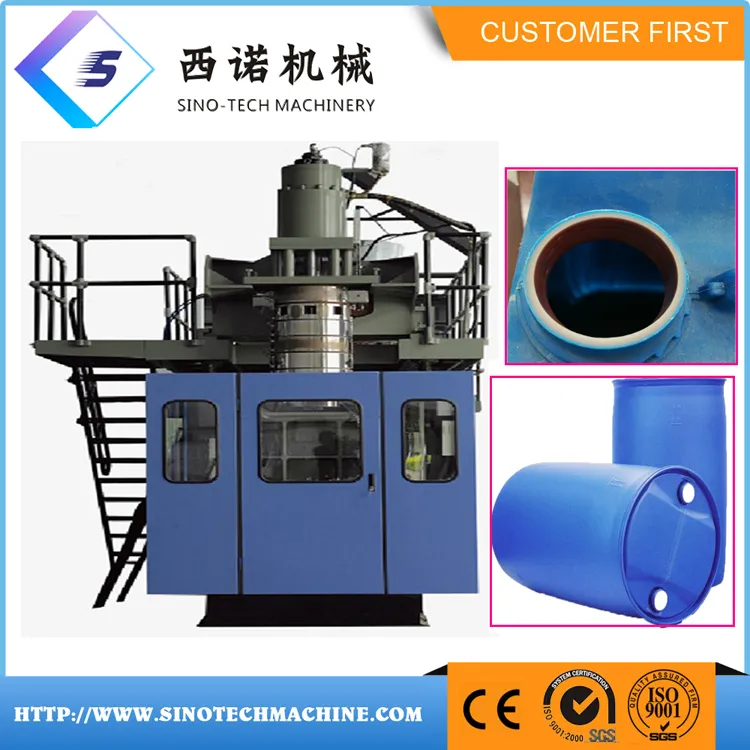

60L 120L 160L 200L 220L Plastic Drum Chemical Barrel Blow Molding Moulding Making Machine

200L 220L Plastic Drum Chemical Barrel Blow Molding Moulding MachineAutomatic plastic drum blow molding machineOur company is very famous at 250L blow molding machine, the advantage of this machine is:Plasticizing Part. Plasticizing system is specialty design for HMWHDPE material and the plasticizin......

Send Inquiry

Product Description

Automatic plastic drum blow molding machine

Our company is very famous at 250L blow molding machine, the advantage of this machine is:

Plasticizing Part. Plasticizing system is specialty design for HMWHDPE material and the plasticizing volume is reaching 360kg per hour, the electric current is 220A

Mould part. We used American software to design the flow passage of the mould. The material is well-distributed

Auto bottom blowing unit. We improved it for six years, it prevents water leak and oil leak

Save energy. Hydraulic system is only using 22KW oil pump motor

This machine can produce at least 20 pcs per hour according to the weight of the product is round 10kg

Technology Parameter of TDB-250A

| Item | Code Item | Standard Code | Manual | Note |

| Extruder (Main extruder) | Max. Capacity | 250L | ||

| Main screw | φ120mm | Screw type: Mutations isolated mixing energy saving screw Barrel type: IKV forced feeding structure | ||

| Screw L/D | 32: 1 | |||

| Screw material | 38CrMoALA | |||

| Max. Extruder consumption | 360Kg/Hr. | Take HMWHDPE for example, change with material density | ||

| Twisting transition method | Electrical machinery, Gear box, Leather belt transmission | Hard gear surface decelerator | ||

| Driving motor | 132KW | |||

| Screw rotate speed | 5---60r/min | |||

| Ahead/back adjusting | Yes | |||

| Up/down adjusting | Yes | |||

| Heating mode | Ceramic heating ring, temperature control precision ±1% | |||

| Temperature control zone | 5 | Japan MTSUBISHI | ||

| Heating power | 40KW | |||

| Cooling for blower | 5 | |||

| Cooling function | Yes | Cooling water | ||

| Clamping unit (Mold opening/closing unit) | Structure | With patented TONGDA two-bar timing clamping structure in high speed and high force, to achieve quality products. | ||

| Clamping directions | Ball rail | For high precise location for longer service life. | ||

| Clamping speed | 250mm/sce; 15m/min | |||

| Platen dimension | 1320*1650 mm | (W*H) | ||

| Max. Mold dimension | 1100*1720 mm | (W*H) | ||

| Mold opening stroke | 1000 mm | |||

| Platen distance | 800~1800 mm | Min.~Max. | ||

| Clamping force | 770 KN | |||

| Mould thickness scope | 810~1000 mm | |||

| Fixing pattern of mold | Mold press platen | |||

| Mold opening/closing stroke control | Inducing Switch+moving | Discriminate mold opening/ closing end, mold opening/ closing slow speed, | ||

| Light Electric Safety protect | Taiwan FOTEK | |||

| Die head | Form | Accumulator | First in, first out | |

| Material | 38CrMoALA, inner mirror treatment | |||

| Accumulator volume | 22L | |||

| Output of injecting | 16.5Kg | HDPE, density: 0.75g/cm3 | ||

| Die dimension size | φ120~ 620mm | Min.~Max. | ||

| Heating method | Stainless steel heating ring, precision + 1% | |||

| Temperature control zone | 6 | |||

| Blow-air | Yes | |||

| Adjusting of parison thickness | Yes | MOOG 100-point | ||

| Injecting stroke control | Accumulator electronic ruler + limit switch | |||

| Adjusting method of thickness | Inner mold adjusting | |||

| Adjusting output at axial direction | + 5mm | |||

| Injecting pressure | 75~140mm | TONGDA 10-point pressure adjusting control | ||

| Max. Injecting speed | 1.6kg/sec | |||

| Top blowing | Blow-air control method | Discriminate high/low blow-air | ||

| Side blowing | Blow-air control method | Discriminate high/low blow-air | ||

| Bottom blowing | Blow pin stroke control | Inducing switch | Discriminate blow pin up/down end | |

| Blow-air control method | Discriminate high/low blow-air | |||

| Blow pin cooling function | Cooling water | 1-in 1-out cooling system | ||

| Blow pin supporting material | Yes | Changeable | ||

| Adjusting of blow pin position | Ahead/back, left/right, up/down adjusting | |||

| Mechanical hand | Running method | Germany FESTO | ||

| Direction control | Ball rail | High precise and speed | ||

| Electric system | Temperature control | MITUSBISH | MITUSBISH, PID control | |

| Load protection | ||||

| Movement control | MITUSBISH PLC | |||

| Operation interface | Human-machine interface | Taiwan HITECH | ||

| Time setting | Touch screen | |||

| Oil pressure system | Main motor | 22KW | Split flow pump & energy accumulator | |

| Main oil pump | American DENISON | |||

| Movement control method | Proportion pressure control | 0~999 | ||

| Direction control | Japan YUKEN hydraulic direction control valve | |||

| Max. Pressure | 160kg/cm2 | |||

| Air pressure system | Direction control | Taiwan AIRTEC | ||

| Pressure control | Separated | |||

| Max. Pressure | 8kg/cm, 1.6m3/min | All air pipes are connected by PU pipe | ||

| Other material | Lubrication way | Butter | ||

| Oil pressure cooling | Cooling effect is achieved by oil pressure cooling | |||

| Mold cooling | Separated cooling water resource, use 5-in 5-out fix (single side) | |||

| Gear box, hopper place, die dimension cooling | Use separated cooling water circuit, insure cooling effect | |||

| Servo pump | Variable-volume pump | |||

| Power of servo pump motor | 11KW | |||

| Installed capacity | 230KW | |||

| Average energy consumption | 120KW | |||

| Overall dimension | L*W*H | 8000*2900*5500(mm) | ||

| Weight | 38TON |

Machine Pictures

After-sales service

1. We offer you the free machine operation training happened in China.

2. Offering the free testing and installing of the machine in the buyer factory, but the fee of the visa, the ticket, food and living should be in the buyer's charge.

3. The spare parts of the machine and the auxiliary machine can be supply by us.

4. The guarantee of the machine is one year under the normal operation.

5. We offer the customer the technology for free for all life time.

Any question,please call me: