Auto-Deflashing Oil Barrel Plastic Blow Molding Machine 5L

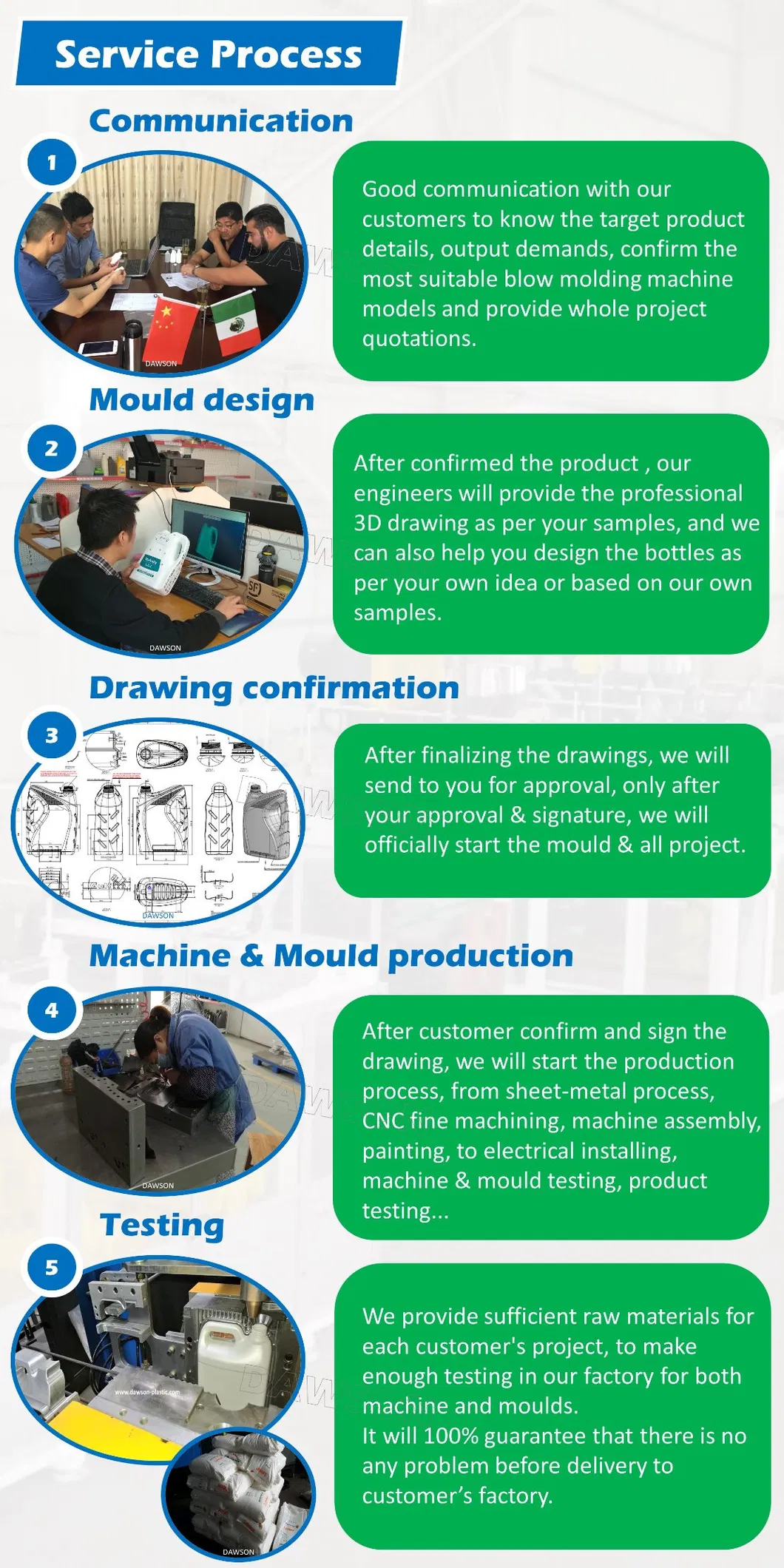

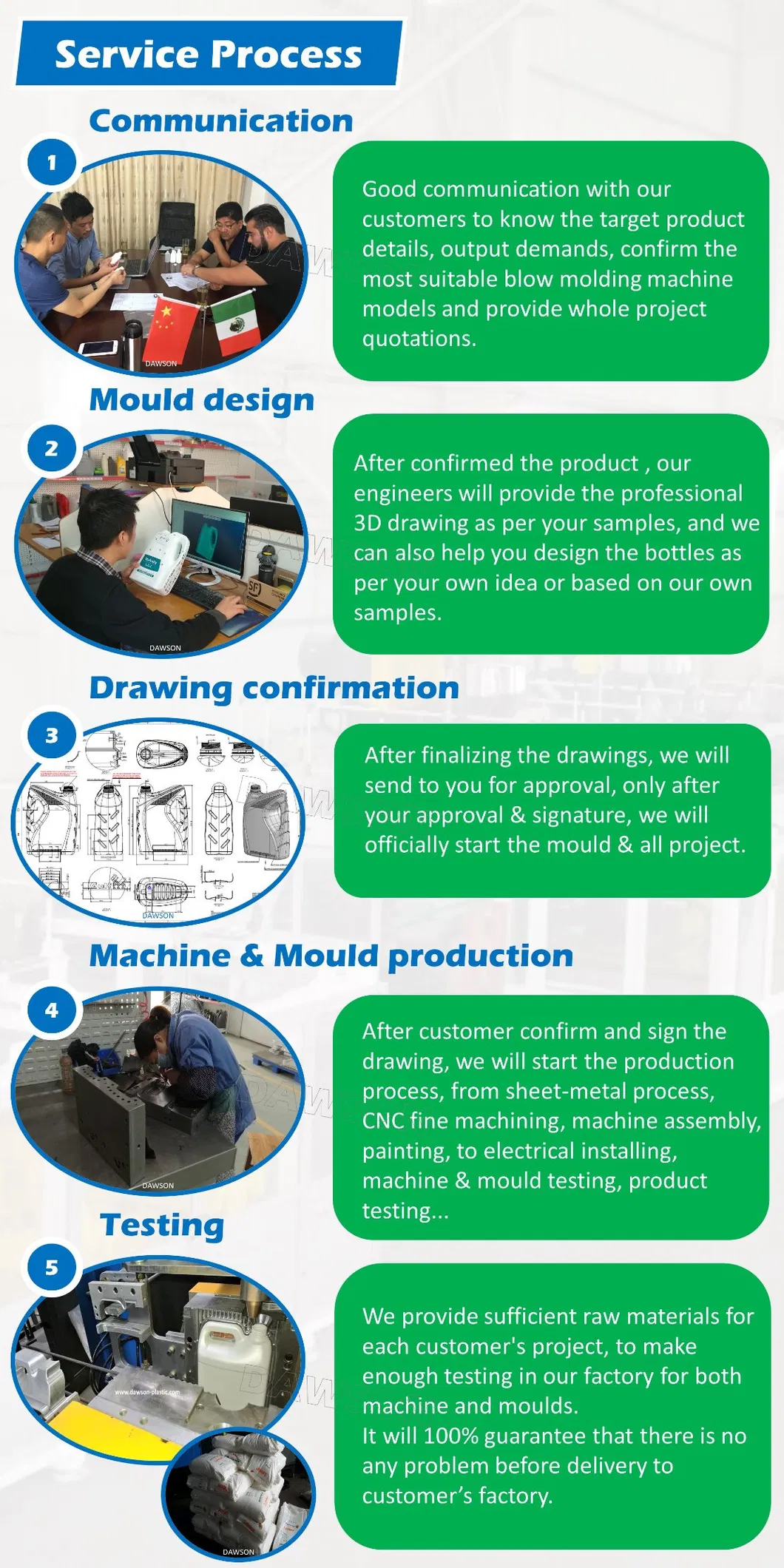

DAWSON MACHINERY & MOULD GROUP***EXTRUSION BLOW MOLDING MACHINE EXPERT***Our customers are all around the world. Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India, Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Ken......

Send Inquiry

Product Description

DAWSON MACHINERY & MOULD GROUP

***EXTRUSION BLOW MOLDING MACHINE EXPERT***

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India, Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia, Venezuela, Peru....

Double station blow molding machine KS90II series

***EXTRUSION BLOW MOLDING MACHINE EXPERT***

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India, Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia, Venezuela, Peru....

Double station blow molding machine KS90II series

Suitable for making 2-15L HDPE Jerry cans, bottles, gallons, jars...

KS90II-3 3 head suitable for 2L & 3L bottles

KS90II-2 Double head for making 5L bottles

KS90II-1 Single head can making 8-15L bottles

KS90II-3 3 head suitable for 2L & 3L bottles

KS90II-2 Double head for making 5L bottles

KS90II-1 Single head can making 8-15L bottles

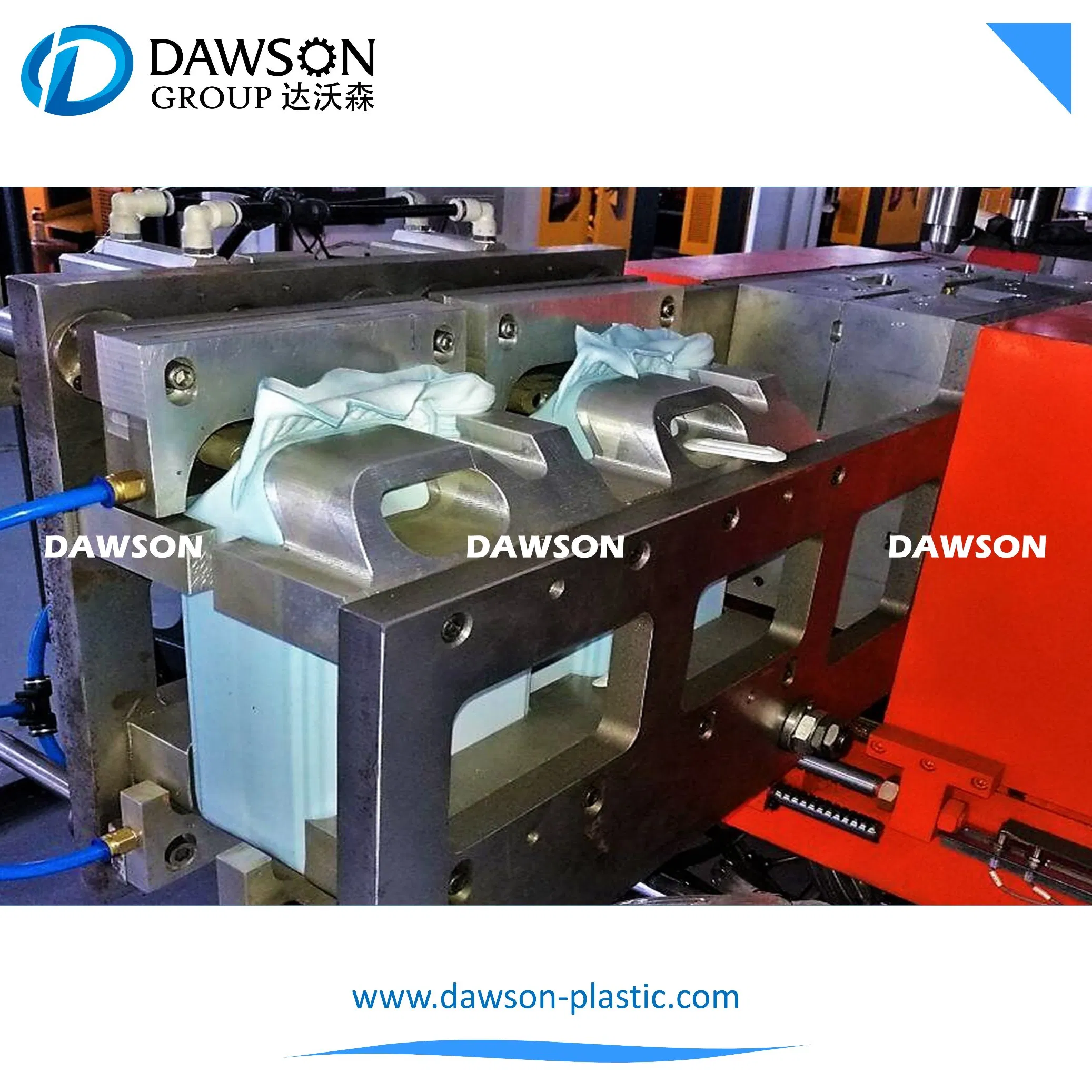

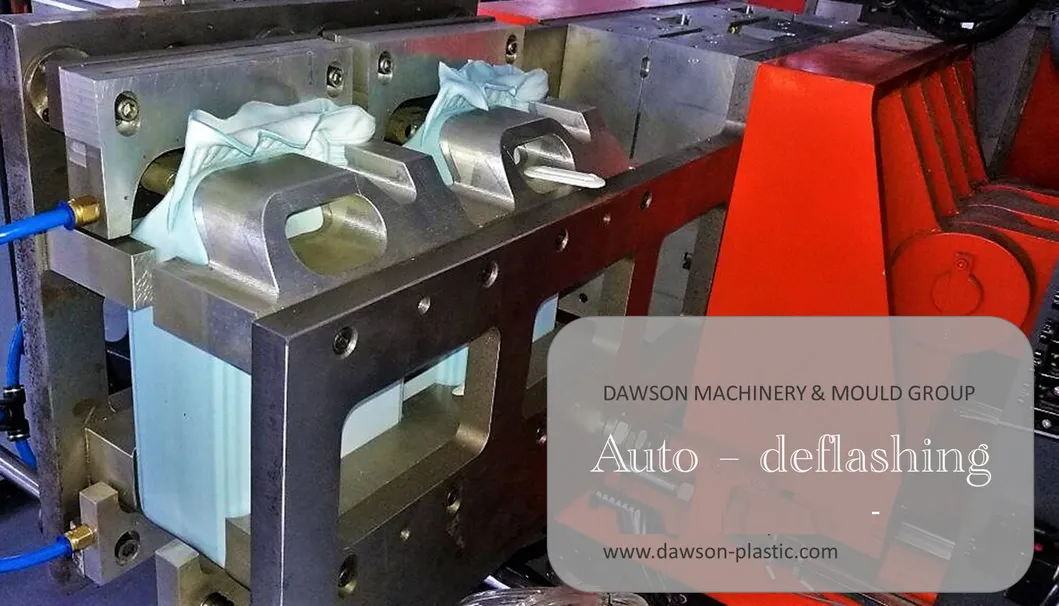

Auto-deflashing system

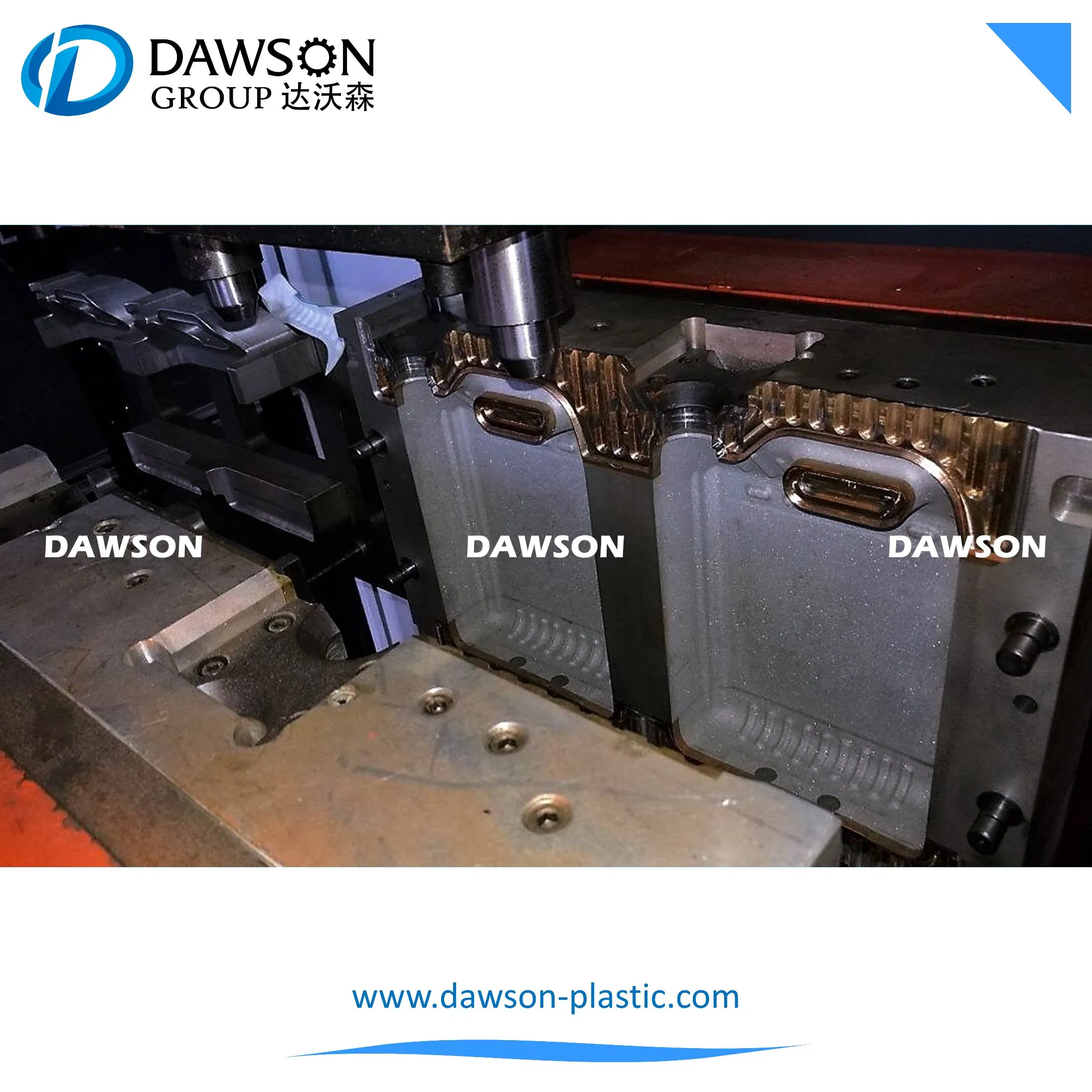

Aluminium with Beryllium Copper Mould

Equiped with MOOG parison controller for thickness control

Available to connect with conveyors , leak tester and auto bagging machine for fully automatic system

Aluminium with Beryllium Copper Mould

Equiped with MOOG parison controller for thickness control

Available to connect with conveyors , leak tester and auto bagging machine for fully automatic system

Technical Parameters

| Basic parameters | Suitable material | HDPE,PP | ||

| Max volume | 5L | |||

| Output capacity | 280~300 pcs/h | |||

| Size | 3.4×5×2.6(M) | |||

| Weight | 8.3T | |||

| system | Specification | Parameters | Note | |

| Plasticizion system | Summarize | High efficient low power consumption plasticizion system,transducer control,self-protect function when started at low temperature | ||

| Reducer | Hard finishing,High intension,Low noise reducer | |||

| Screw | ∮80mm,L/D ratio 25,110kg/h 38CrMoALA | Cooling system available | ||

| Heating Zone | 4 Aluminum Heater | Automatic heating | ||

| Heating power | 16KW/H | |||

| Cooling Fan | Separate cooling system for heaters | Automatic cooling | ||

| Extrusion system | Single Die Head System | |||

| Summarize | High-grade alloy steel, center feeding Accumulation head,2.5L capacity of head | |||

| Die head number | 1 | |||

| Center distance of die heads | / | |||

| Max die mouth | 320 | |||

| Extruder Motor | 30kw SIEMENS MOTOR | |||

| Clamping system | The most advanced clamping system -- Bend arm translational type mould closing mechanism. The utility model technical problem to be solved: to design a bent pan-type clamping mechanism, the use of open, the role of the clamping cylinder and control, through the rational allocation of torque bent to promote pan rail template horizontal movement, complete open mold, mold, clamping the plastic molding process; make rational allocation of maximum clamping force. | |||

| Summarize | High intension, rigidity, center mold locking, stable mould opening and advanced clamping system | |||

| Clamping force | 220 KN | |||

| Distance between platens | 450~900mm | |||

| Mould template | 650× 550 | |||

| Mould material | Steel S136H or Aluminium with beryllium copper | |||

| Electric system | ||||

| Summarize | PLC+ touch screen(man-machine interface)standard extrusion blow molding machine controlling system(AUTO monitoring, fault-alarm, auto counting ,auxiliary function available) | | ||

| Operate interface | Touch screen, automatic self-diagnose alarm system | |||

| Parison control | MOOG 100 points controller | |||

| Parison control valve: MOOG servo valve | ||||

| Temperature control | Automatic temperature control module | |||

| Movement control | Japanese Mitsubishi, Chinese/English Version | |||

| Motor : SIEMENS motor | ||||

| Electric protection | Ampere overload, electric short circuit self-protection function | |||

| TOTAL rated power | 63 kw | |||

| Average power consumption | 40 kw | |||

| Inverter | DELTA (TAIWAN) | |||

| Hydraulic system | Summarize | Multiple function hydraulic integrated block Proportional control, high efficient | ||

| Oil pump motor | Three phase asynchronous motor 11kw servo motor (380V/220V,50/60HZ) | |||

| Oil pump | double vane pump | |||

| Valves | Imported oil pump valves and connections YUKEN | |||

| YUKEN Hydrulic valve Precision control More safe and easy to operate and maintenance Also YUKEN series avoid any leakage problem both inner or outter, which makes the all operation reliable and safe. | ||||

| Oil pipes | Double layer overpressure resistant | |||

| System pressure | LP 100 bar / HP 130 bar Threads of hydraulic block use of screw joint GE(ISO 1179) | |||

| Cooling system | Post cooling by cooling air and cooling water with Aluminum Mask | |||

| Pneumatic system | Summarize | Taiwan AIRTAC pneumatic system | ||

| Air pressure | 0.6~0.8Mpa | |||

| Air displacement | 2.2 M3/min | |||

| Electromagnetic valve | Taiwan AIRTAC | |||

| Cooling system | Summarize | Separate cooling system of mould, barrel and oil system | ||

| Cooling medium | Water | |||

| Water flow | 100L/min | |||

| Water pressure | 0.4-0.6MPa | |||

CONFIGURATION

| COMPONENTS | BRAND | ORIGIN |

| PARISION CONTROL SYSTEM | MOOG | JAPAN |

| PARISON CONTROL VALVE | MOOG | JAPAN |

| PARISON CONTROL TRANSDUCER | MOOG | JAPAN |

| TEMPERATURE CONTROL MODULE | MITSUBISHI | JAPAN |

| PLC | MITSUBISHI | JAPAN |

| COLORFUL TOUCH SCREEN | HITECH | TAIWAN |

| HYDRAULIC PUMP | HYTEK | TAIWAN |

| HYDRAULIC VALVE | HYTEK | TAIWAN |

| OIL TUBE & JOINT | PACKER | U.S.A |

| OIL FILTER | PACKER | U.S.A |

| HYDRAULIC OIL SEAL | VALQUA | JAPAN |

| INTERMEDIATE RELAY | OMRON | JAPAN |

| CONTACTOR | SCHNEIDER | FRANCE |

| INVERTER | DELTA | TAIWAN |

| AIR SWITCH | SCHNEIDER | FRANCE |

| PNEUMATIC VALVE | AIRTAC | TAIWAN |

| PNEUMATIC SWITCH & CONTACTOR | LG | KOREA |

| LINEAR GUIDE RAILS | HIWIN | TAIWAN |

| HYDRAULIC MOTOR & SCREW MOTOR | SIEMENS | GERMAN |

| HARD GEAR BOX | GUOMAO | TAIWAN/CHI |

Related Category

Plastic Machinery

Woodworking Machinery

Blow Molding Machine

Plastic Recycling Machine

Injection Molding Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.