One Step 90kw Used Pet Sheet Extrusion Line with 3-Roller Calander Bottle Making Machine

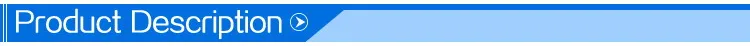

The machines are three stations, injection preform, blow/stretch blow and product release. The raw material comes from the hopper to theinjection screw to inject preform; the plate rotates preforms to blow/stretch blow station with themselves heat, without any reheating for blowing,Then the product ......

Send Inquiry

Product Description

The machines are three stations, injection preform, blow/stretch blow and product release. The raw material comes from the hopper to the

injection screw to inject preform; the plate rotates preforms to blow/stretch blow station with themselves heat, without any reheating for blowing,

Then the product will rotate to release station and drop down, it is fully automatically cycle rotation working mode.

Comparing the traditional blow machine, JASU one step blow machines possess lots of advantages, first,no needreheating, with the preforms

themselves heating when injection to blow,highly save energy and shorten molding time, more importance is that one step machines have cut

off the transfer process from two step blow machine, avoidcontamination causing by transfer process, especially for Pharmaceutical and food

containers,save labor force andtransfer cost,decrease the production cost and increase product competitive power.

Model ISB800-3 and ISB800A-3 (larger size)

For PC, PS,PMMA lamp cover, LED light lampshade,Christmas flash light, garden and street light.

For PET high transparent,much thinner wall, cosmetic bottle 10ml to 500ml, PET wide neck jar, PET pharmaceutical bottle

For PP high transparent, baby feeding bottle, sport bottle

For PCTG, Tritan drinking water bottle, sport bottle.

Mould and tooling, we have mould workshop ourselves, advanced CNC machine and smart design engineers,we can treat different material and

size products from different customers over the world.

Auxiliary machine,we will equip you with the necessary quality auxiliary machines to ensure the production plan running well,we can supply you

one-stop service.

Model | ISB 800-3 | |

| Injection Part | ||

| Screw Diameter | 40mm | |

| Screw L/D Ratio | 20.5:1 | |

| Screw Speed | 0-190RPM | |

| Theoretical Injection Capacity | 238cm3 | |

| Injection Pressure | 174Mpa | |

| Max. Hydraulic Pressure | 140Kg/cm | |

| The Actual Injection Quantity(PS): | 225g(ps)/8Oz | |

| Screw Stroke: | 190Mm | |

| Clamping Part | ||

| Blow Clamping Force: | 80Kn | |

| Clamp Tonnage: | 400Kn | |

| Wheel Diameter: | 800mm | |

| Max. Height of Bottle: | ISB:145/IB:140 | |

| Open Vertical Mode Trip: | 430mm | |

| Others | ||

| Max. Pump Pressure: | 16Mpa | |

| Motor Oil: | 18.5Kw | |

| Electric Power: | 12.2Kw | |

| Oil Tank: | 400L | |

| Overall Dimension(L*W*H): | 3.8m*1.45m*3.0m | |

| Weight: | 5000kg | |

With the increasing requirement of high quality and elegant appearance in the packing field of food, beverage, and cosmetic, the plastic

containersmade by the old style extrusion blowing machine cannot meet the customer's demand any more. However, by one step injection

stretch blow molding machine, from the raw material to productis processed by one step.The whole process includes preform injection,stretch

blow and release. No trimmings, No runner gate material, but perfect neck, bottom and line, higher transparent, higher rigid. Stretch-blowing

molding

products come with thinner wall andsave more material.

One step Injection Stretch Blow Molding Machine completes a high speed molding without preform reheated. With the heat from preform injection

to stretch and blow, unnecessary reheating and shorten preform cooling time to save energy.

One step Injection Stretch Blow Molding Machine optimizes the working structure, removes molding disadvantage factor, cuts off the complicated

working procedure to ensure molding more reliable and increase the reject rate.

One step Injection Stretch Blow Molding Machine decrease the convey cost and avoid the second contamination, special for food and pharma

ceutical company. For example, to transit the 19g 500ML bottle, if the 1m³trunk used, it can load 1024 bottles, or 9280 preform, but if by the raw

material that can produce 56421 bottles. The logistic cost of material comparing with transiting bottles can be reduced by 98.2%; Comparing with

the cost of transiting preform, the cost can be reduced by 83.6%.

Compare with One-step and Two-step:

| Molding | Process | Structure | Manpower/ Energy/ Space | Product Quality |

| One-step | From preform to product | One machine | Little | Not affect by damp and less pollution; Various kinds of shape |

| Two-step | Injection and blow molding are two separated process | 1.Injection molding machine 2.Preform transiting machine 3.Reheating, stretch and off-moulding machine | More | Easy affect by damp and polluted; Singleness shape |

JASU One Step Injection Stretch Blow Molding MachineModel ISB800-3/ISB800A-3 advantages are as follows:

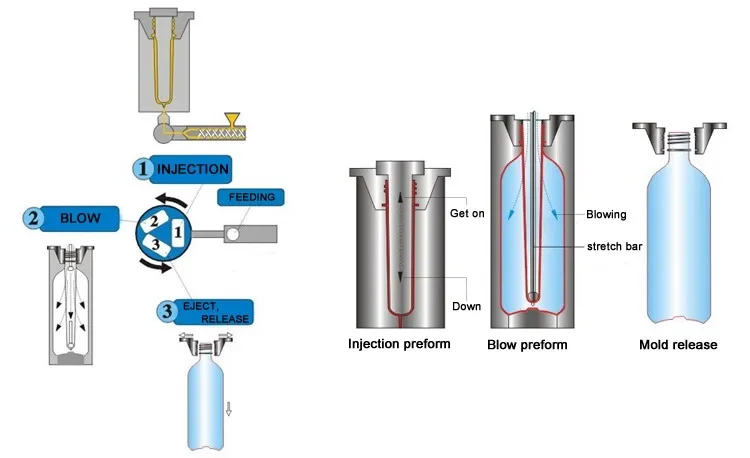

1. The wheel rotation is driven by electrical servo motor, not hydraulic.

2. Full automatic controlling system, easy operating.

3. The temperature of material barrel and hot runner is controlled accurately by PIT.

4. More cost is saved than traditional machine.

5. Compact structure; less space needed.

6. Injection:

Hot runner and temperature control device are standard configuration. Only change mold for making a new product;

Stretch Blow:

Hydraulic mold clamping, core insert, stretch blow and bottom molding are standard configuration;

Product Release:

Equipped with a standard ejector.

GUANGZHOU JASU MACHINE CO., LTD researched, designed and manufactured BLOW MACHINES since 1989. Specialize in manufacturing

GUANGZHOU JASU MACHINE CO., LTD researched, designed and manufactured BLOW MACHINES since 1989. Specialize in manufacturingone step INJECION BLOW MOULDING MACHINE and INJECTION STRETCH BLOW MOLDING MACHINE. Attracting the market's concern

for the solutions we supplied to the high quality, high precision plastic containers with low cost and low energy consumption.

More than 100 employees and 30 professional technicians dedicate themselves to JASU® brand series machines, our R&D department devotes

to constantly developing new blow technology. We have set up 30 representative offices and 24hours maintenance service network throughout

China.

JASU® has established a high reputation from customers home and abroad, specially the oversea customers from Southeast Asia, Middle East,

Africa, Europe, South America, etc. At the end of 2014, the export amount took up 60% of the yearly sales.

Located in Pearl River delta area, closed to vessel port and air transportation services, special near HONGKONG air port, we have the competitive

advantage of a fast delivery system and centralized supply chain center. We sincerely wish to invite the trade partners and import buyers to visit our

showroom, as well as the workshop, to discuss the possible cooperation.

Welcome to Visit Our Company. For Further Informations, Please feel free to Contact us.

If you are interested in our products

We have someone who tell you Solutions Products