Home > Products > Injection Molding Machine > EVA Foaming Injection Moulding Slipper Shoe Machine with Servo Motor System Eight Station

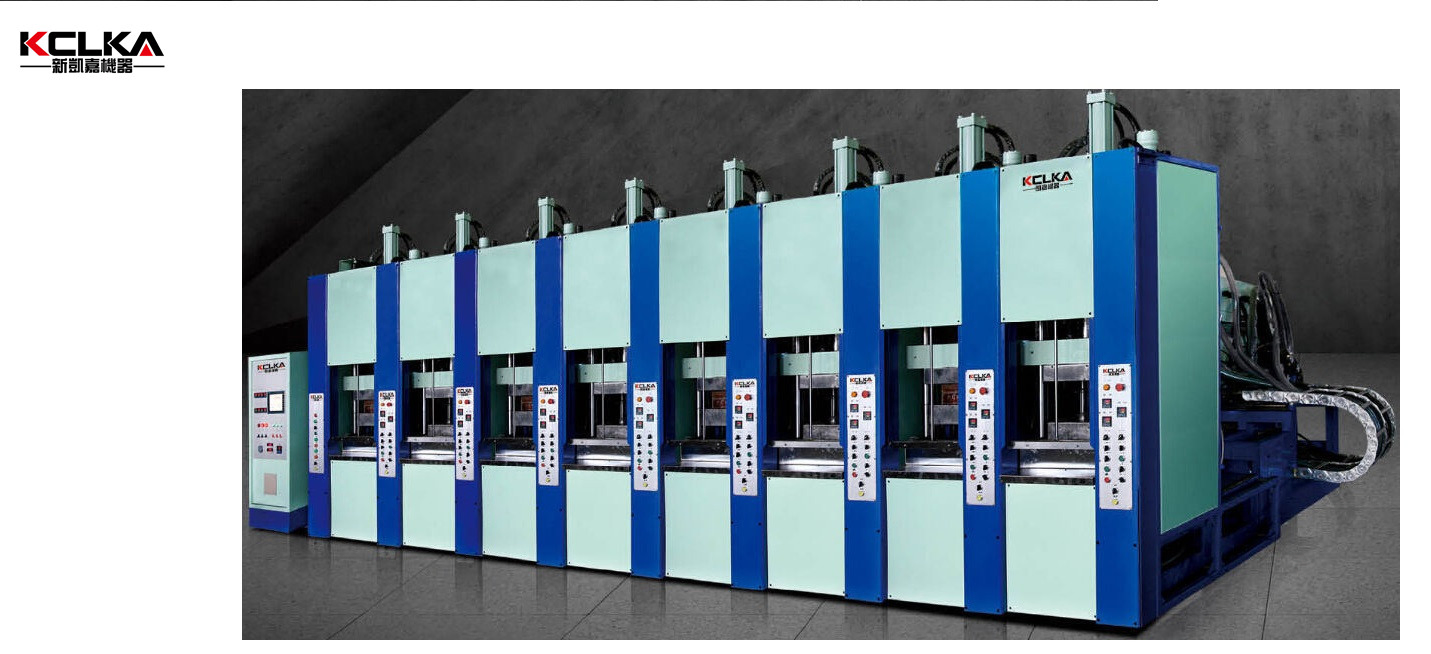

EVA Foaming Injection Moulding Slipper Shoe Machine with Servo Motor System Eight Station

1.Its product range includes EVA slippers, sandals, clogs, mid-sole, sport protectors and various kinds of shoes and shoe accessories all depends on the EVA shoe mould and can also make EVA wheel for toys and so on.2.The clamping force can be increased from 150 to 210 tons, according to your require......

Send Inquiry

Product Description

1.Its product range includes EVA slippers, sandals, clogs, mid-sole, sport protectors and various kinds of shoes and shoe accessories all depends on the EVA shoe mould and can also make EVA wheel for toys and so on.

2.The clamping force can be increased from 150 to 210 tons, according to your requirement.

3.The foam EVA injection molding machine is fully hydraulic and automatic operation except taking out product.

4.It is PLC controlled, its humanized parameter computer operation interface provide quick and exact terms of production.

Character:

1.Low operation height,Operation height in accord with human engineering

2.Extra height opening stroke

Act by fixed opening stroke: 350mm, which is not affected by any mould thickness changes and

3.available for 2plates mould,Mould thickness adjusting mechanism

Mould adjusting scope: 100-200MM

4.Rapid mould opening ,Act by toggle mechanism which opens the mould rapidly

5.Speedy injector movement

Driven by linear-track, allowing speedy moving and precise positioning,Energy saving design

6.No need water circulation for mould station

7.Space saving design,Put oil tank together with injection base, which makes the structure compact and saves more space.

Technical Description.

| Item | Unit | EK3-8E2 |

| Work Station | station | 8 |

| Clamping Force | ton | 180 |

| Mold Plate Size | mm | (290*550)*2 |

| Mold Height | mm | 100-230 |

| Mold-opening Stroke | mm | 350 |

| Injection System | ||

| Injector | 2 | |

| Diameter of Screw | mm | Φ65 |

| Injection Cap(Max) | cm³ | 920 |

| Injection Pressure | kg/cm² | 0-130 |

| Injection Speed | cm/sec | 0-10 |

| Rotating Speed of Screw | r.p.m | 0-190 |

| Temperature Control | section | 4 |

| Electricity Consumption | ||

| Heater Barrel | kw | 9.8*2 |

| Heating Plate | kw | 102.4 |

| Hydraulic System | kw | 51.9 |

| Vacuum Pump | hp | 1.5 |

| Cooling Fan of Barrel | hp | 1 |

| Total Electricity | kw | 155.8 |

| Oil Tank Size | L | 1000 |

| Machine Weight | kg | 33000 |

Its daily productivity is 2*18*8*24=6912 pairs by theory calculation.for 1 pair in 1 mould,For 2pairs in 1 mould is 6912*2=13824 pairs per 24hours

FAQ:

FAQ:1.I have never purchased this kind of products from China, can i trust you?

We are professional manufacture that originally established in 2003.We exported our product to all around the world.We also work with many "big names" which have high global reputations. And you are more than welcome to visit us at any time.

2.Are EVA shoes safe?

Yes, EVA shoes are safe.

3.Which soles is best EVA or RUBBER?

EVA soles.

Related Category

Plastic Machinery

Woodworking Machinery

Blow Molding Machine

Plastic Recycling Machine

Injection Molding Machine

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.