Toggle Clamping Hydraulic Injection Moulding Machine with T Slot

Servo Power-Saving Injection Molding Machine (KWS Series)Overview: Characteristic ClampInjectionControlServo motor controlTechnical ParameterApplicationCharacteristic:» Linear guide for injection carriage could lower the wear and tear, and make the injection control precise and stable. (......

Send Inquiry

Product Description

Servo Power-Saving Injection Molding Machine (KWS Series)

Overview: Characteristic ▪ Clamp•Injection•Control•Servo motor control•Technical Parameter•Application

Characteristic:

» Linear guide for injection carriage could lower the wear and tear, and make the injection control precise and stable. (Optional)

» T slot mould platen

» Apply international famous brand electric & hydraulic components.

» The injection base is modularized and could choose different matching type in accordance with injection volume.

» Smooth the mold opening speed curve design, and add the speed command to reduce the machine vibration.

» It has excellent precision control with the weight error of finished product is about 0.7% to 0.4%.

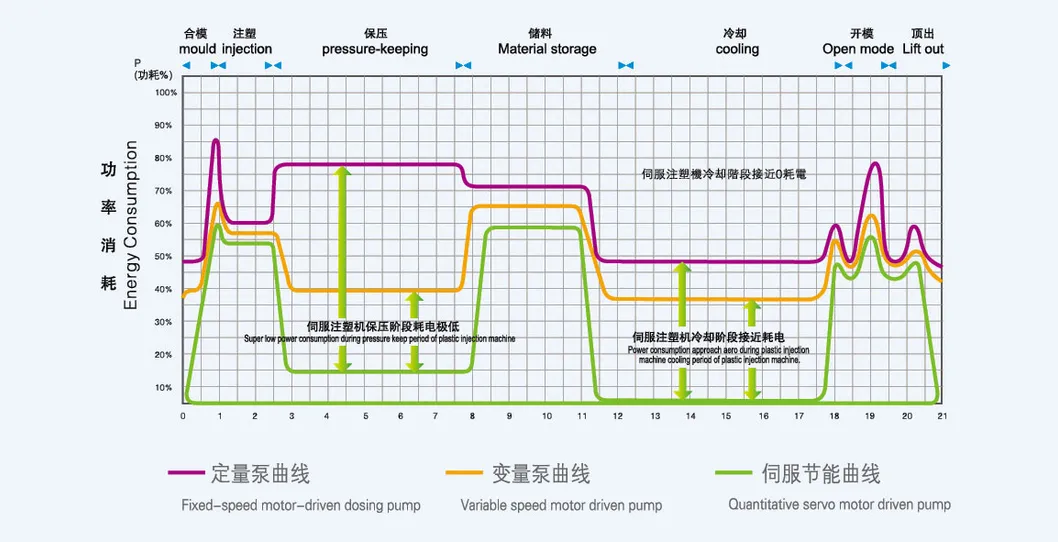

» Adopted servo power-saving system which could reduce the energy consumption 40%- 70%.

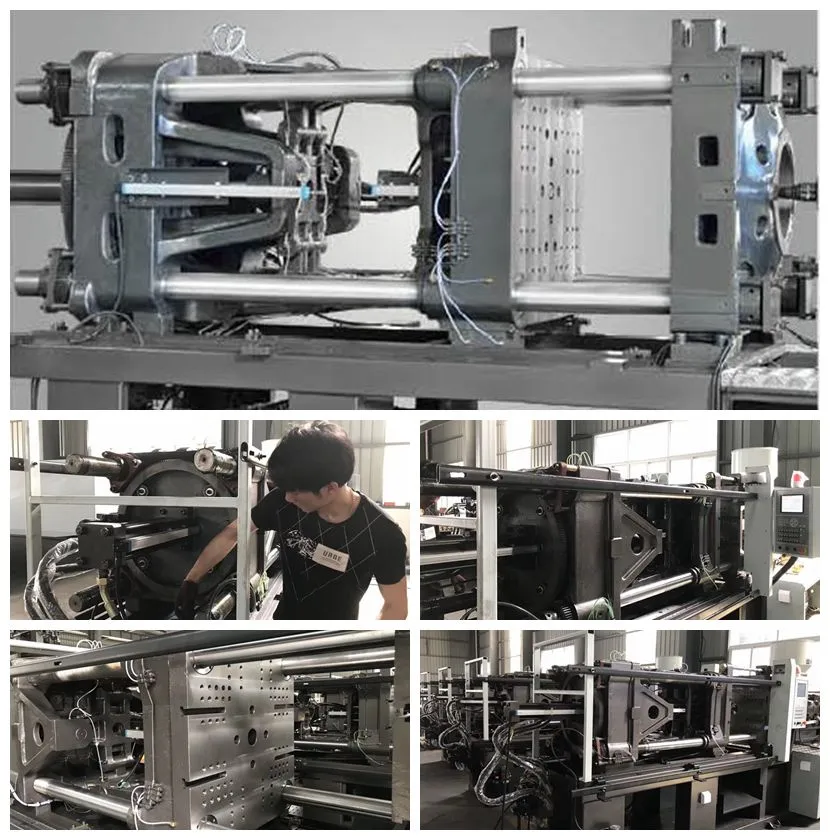

Clamp:

» Hydraulic (optional), mechanical and electric triple inter-locked safety device, mould close is not realized when open any one of the safety door.

» Low pressure mould protection device, protect mould from damage due to any foreign objects.

» Use hydraulic ejector pin to adjust traverse, eject forward and backward pressure & speed, multi action available.

» Use high precise linear transducer to inspect position, multi-zone control mould opening stroke speed and position, accurately positioned.

» Strengthen moving platen wear resistance guide way.

» Centralized lubrication system guarantee uniform oil supply for every lubrication dots.

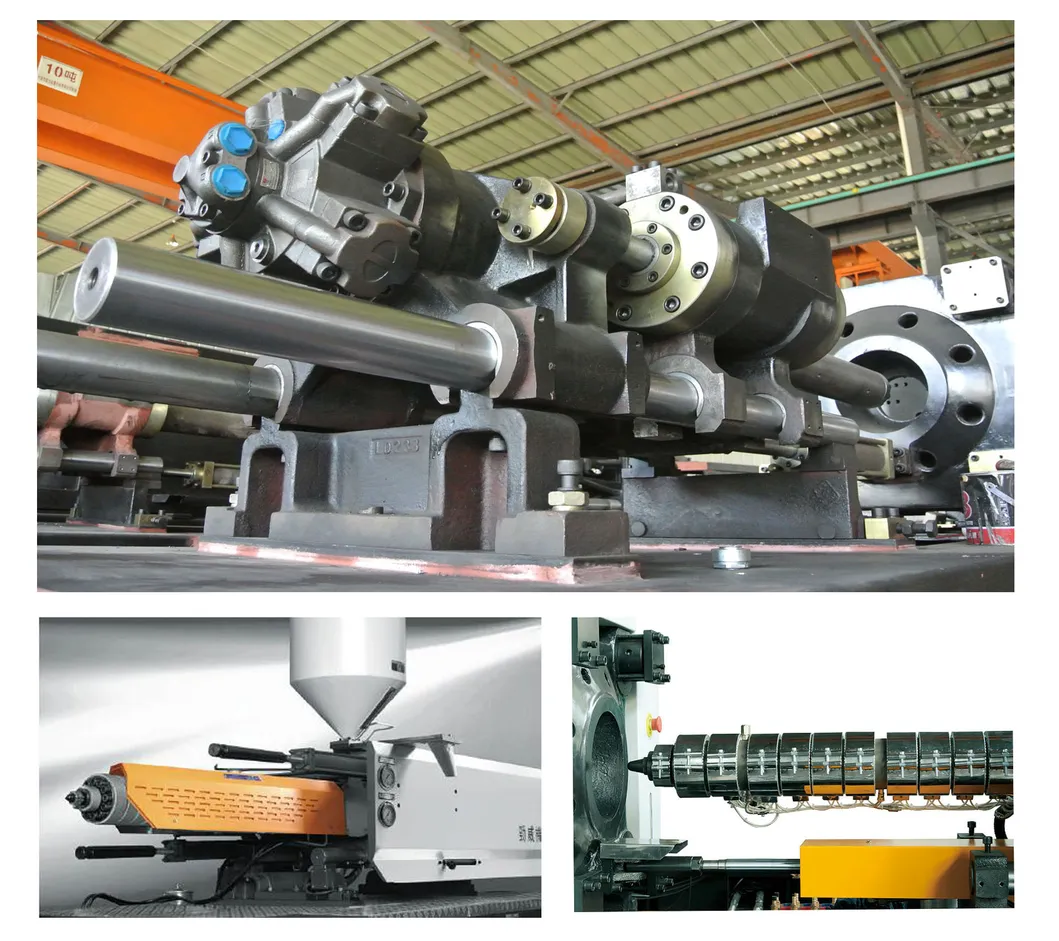

Injection:

» Injection unit applies double guide post support, equip with fast and strong dual-cylinder balancing injection structure.

» Optimized design screw set, achieve excellent plasticizing effect.

» Using high quality nitride alloy or chrome coated screw and nitride barrel.

Control:

» TFT LCD color display

» Using high speed DSP processor, time control precision reaches

» High precise displacement transducer system, control precision

» Using fuzzy prediction technology, temperature control precision

» Multi input/ output interface, the interface function can be setting as demand.

» With output programmable function

» Support USB and network interface (optional)

» Parameter data lock protection, with auto save function in case accident power off

» Big data storage capability

Servo motor control:

» Excellent energy saving as compared with the traditional fixed pump injection molding machine, it saves energy 20%-80% under the same working condition.

» Excellent injection molding stability

» Fast response

» Low noise and quiet operation

» Constant oil temperature

Technical parameter:

| Technical parameter | ||||

| Item | Unit Model | KW178 | ||

| Injection unit | ||||

| Screw type | / | A | B | C |

| Screw diameter | mm | 42 | 45 | 50 |

| Shot volume(theoritical) | cm3 | 312 | 358 | 442 |

| Injection weight (PS) | g | 284 | 326 | 402 |

| Injection rate | g/s | 108 | 125 | 158 |

| Injection pressure | Mpa | 178 | 155 | 125 |

| Screw rotation speed | r.p.m | 200 | ||

| Clamping unit | ||||

| Clamping force | KN | 1780 | ||

| Open stroke | mm | 435 | ||

| Space between tie bars(W*H) | mm | 470*470 | ||

| Max. mould height | mm | 520 | ||

| Min. mould height | mm | 180 | ||

| Ejector stroke | mm | 135 | ||

| Ejector force | KN | 39 | ||

| Others | ||||

| Max. Pump pressure | Mpa | 14 | ||

| Pump motor power | KW | 15 | ||

| Heating power | KW | 9.7 | ||

| Machine dimension(L*W*H) | m | 5.05*1.43*2.20 | ||

| Machine weight | t | 5.6 | ||

Application:

The machines applicable industries include general houseware, electronic products, auto parts, packaging, toys and building components etc.