Which Problems Do Durable Multilayer Decking Solutions Solve Better Than Traditional Decking?

2025-10-13

As someone who has worked at Haoyun for nearly two decades, I’ve seen firsthand the frustrations customers face with traditional decking: rotting, fading, mold, warping, constant upkeep, and short lifespans. That’s why I am proud to introduce our high-performance Haoyun brand CO-extrusion Decking solutions — designed to handle the harshest climates, heavy foot traffic, and years of exposure with minimal maintenance.

In this post I want to walk you through what makes multilayer (co-extrusion) decking so robust, how our specific product parameters stack up, and how you as an end user or specifier will benefit. I’ll write this as though I’m speaking from inside the company — because I am — and I’ll use tables and lists so that engineers, architects, distributors, and homeowners all can easily digest the key data.

What Is Multilayer CO-Extrusion Decking and Why Should You Care?

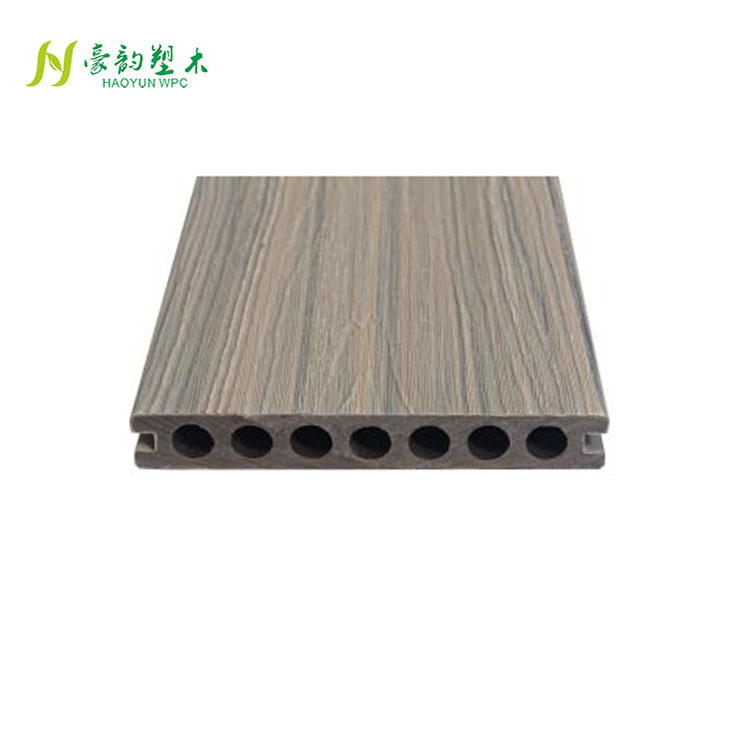

Multilayer CO-extrusion decking (also called capped composite decking or co-extruded WPC decking) is a board composed of a wood-plastic composite core and a protective polymer shell that is extruded simultaneously (not glued on later). This “co-extrusion” process ensures a tight bond between the core and shell, giving 360° protection around the board. Compared with traditional composite decking or natural wood, the multilayer structure helps resist UV, moisture, stains, scratches, mold, and deformation.

Key advantages include:

-

Color retention and fade resistance due to the UV-stabilized cap

-

Scratch / abrasion resistance from the hard shell

-

Low water absorption and mold resistance

-

Reduced maintenance (no need for frequent sanding, sealing, or staining)

-

Longer lifespan under extreme weather conditions

Because we manufacture Haoyun CO-extrusion Decking, these are not just theoretical — they are features we test and guarantee for our own clients.

What Are the Technical Parameters of Our Haoyun Multilayer Decking?

Below is a detailed table summarizing the typical specifications and performance metrics of our co-extruded decking. You can use this to compare against other products or to specify directly in your project documents.

| Parameter | Typical Value | Notes / Range | Why It Matters |

|---|---|---|---|

| Board Size (width × thickness) | 138 × 23 mm, 140 × 23 mm, 145 × 21 mm, 146 × 25 mm, 148 × 23 mm (customizable) | Many standard sizes; we also support custom dimensions | Ensures compatibility with framing and spans |

| Board Lengths | 2.4 m, 3.6 m, 4.0 m, or custom | Flexible for shipping and site handling | Minimizes joints and waste |

| Core Composition | ~55 % wood fiber, ~35 % HDPE plastic, ~10 % additives | Typical blend used in industry Pewen Pisos+1 | Balances structural strength and processability |

| Density | ~1.38 g/cm³ (for 138×23 profiles) | From published technical data Pewen Pisos | Higher density often correlates with stiffness and durability |

| Water Absorption (24h) | ≤ 0.05 % | Very low absorption Pewen Pisos | Helps avoid swelling, delamination, mold |

| Thermal Expansion Coefficient | ~43 × 10⁻⁶ /K (–20 °C to 80 °C) | From published spec sheet Pewen Pisos | Determines how much expansion/contraction to expect |

| Swelling (thickness/width/length) | Thickness ≤ 0.70 %, width ≤ 0.10 %, length ≤ 0.08 % | Published “boiling test” data Pewen Pisos | Key for long-term dimensional stability |

| Bending Strength / Load | ~3,392 N over 350 mm span (for listed profile) | From technical data Pewen Pisos | Indicates how much load the board can carry |

| Warranty / Service Life | 25–30 years typical | Many comparable products also claim 25+ years ONSUN+1 | Gives confidence in long-term performance |

| Surface Treatment & Texture Options | Grooving, embossing, sanding, brushing, painted wood-grain, matte finishes | Fully customizable | Allows aesthetic matching with design intent |

| Certifications | CE, ISO, SGS, FSC (upon request) | Common for export decks | Helps with compliance in many markets |

| Installation Accessories | Hidden clips, edge trims, starter clips, expansion screws, joists | We supply a full accessory kit | Simplifies field installation and ensures consistency |

This level of transparency in parameter data helps you as a specifier or buyer to see exactly what you’re getting, and to compare with competitor decks.

How Do We Ensure That the Multilayer Structure Performs Under Real Conditions?

From my 20 years in product development, I can tell you that having good lab numbers is only half the job — the product must survive real-world stresses: heat cycles, freeze-thaw, heavy loads, rainstorms, UV, and foot traffic.

Here is how Haoyun ensures durability:

-

Simultaneous co-extrusion — we don’t apply a cap later; the core and shell are bonded at the molecular level during extrusion.

-

UV stabilizers & additives — we incorporate UV absorbers, antioxidants, anti-oxidation agents, and color stabilizers to maintain color over years.

-

Full 360° cladding — boards are wrapped on all sides (top, bottom, edges) to minimize water ingress.

-

Rigorous shelf and load cycling — we subject samples to temperature cycling (–20 °C to 80 °C), repeated wet/dry cycles, abrasion tests, and extreme loads.

-

On-site pilot projects and long-term field monitoring — we monitor decks under sun, snow, and coastal environments to validate performance.

-

Strict quality controls — every batch is tested for thickness tolerance, density, bending resistance, water absorption, and color consistency.

When I walk clients through our QC reports, they often comment that the consistency across batches is impressive. That consistency is what gives you peace of mind when ordering large quantities.

In What Applications Does Multilayer Decking Truly Shine?

Because of its robust nature, our Haoyun multilayer decking is ideal in a variety of demanding environments. Here are some use cases and why co-extrusion is advantageous in each:

-

Pool decks / water features — the 360° cap resists water ingress and reduces mold/slip risk.

-

Seaside / coastal decks — UV and salt spray resistance helps maintain appearance.

-

Public boardwalks / parks / piers — high foot traffic, low maintenance, and long life make it cost-effective over time.

-

Rooftop gardens / terraces — lightweight composite core and resistance to moisture make it safer than concrete pavers.

-

Residential patios / balconies — homeowners benefit from the look of wood without the maintenance burden.

-

Bridges / walkway connectors — decks can be designed for structural spans with hidden clips and strong core strength.

Because of these flexible applications, many architects now specify co-extruded decks as the default “premium” option in their outdoor projects.

What Are the Common Questions (and My Answers) You Might Have?

Will the protective shell eventually delaminate or peel off?

No — in our product, the core and shell are merged via the co-extrusion process, not via adhesives. We have never observed delamination in our long-term monitoring.

How much expansion gap should I allow?

Based on the thermal expansion coefficient (~43 × 10⁻⁶ /K) and typical board lengths, we recommend allowing expansion gaps of 3–5 mm every 3 meters, or per manufacturer’s guidance. Precise spacing depends on local temperature extremes.

Can you cut or notch these boards on site?

Yes — you can use standard woodworking tools (circular saw, router, jigsaw). Just be sure to seal the cut edges (we supply edge-seal lacquer) to maintain 360° protection.

Is slip resistance good enough for wet conditions?

Yes — we offer anti-slip surface textures and grooved finishes to improve safety. For poolside decks, we can supply fine grit or micro-textured finishes for added traction.

What about color fading?

Because of UV absorbers and stabilizers embedded in the shell, we can guarantee minimal fading for up to 10 years under typical outdoor conditions (per our accelerated weathering tests).

What is the cost comparison with natural wood or standard composite?

Upfront costs are higher, but the lifecycle cost is generally lower because you avoid frequent maintenance, replacements, sealing, and staining over time. Many customers view our product as a “buy once and forget” solution.

How Do You Specify or Order Haoyun Multilayer Decking for Your Project?

Here is a checklist you (as developer, architect, builder, or distributor) can follow:

-

Choose board dimensions (width, thickness, length)

-

Select the surface texture / finish (groove, embossing, brushing, etc.)

-

Pick the color(s) (standard palette or custom)

-

Determine expansion gap design, joist spacing, fastener system

-

Order matching edge trims, starter clips, expansion screws, and accessories

-

Review sample boards for color match and fit

-

Provide site handling, layout, and installation guidelines to your crew

-

After installation, share a few photos & feedback — we monitor field performance

We provide full set of CAD / BIM files, installation guides, and training support to make specification and installation smooth.

We at Haoyun believe that outdoor decking should not be a recurrent headache. You deserve a durable, beautiful deck that lasts decades with minimal fuss.

If you are ready to upgrade your outdoor space or project with our high-quality multilayer CO-extrusion decking, please contact us for samples, technical datasheets, or quotations. Leave an inquiry or contact us now and one of our sales engineers will respond promptly.