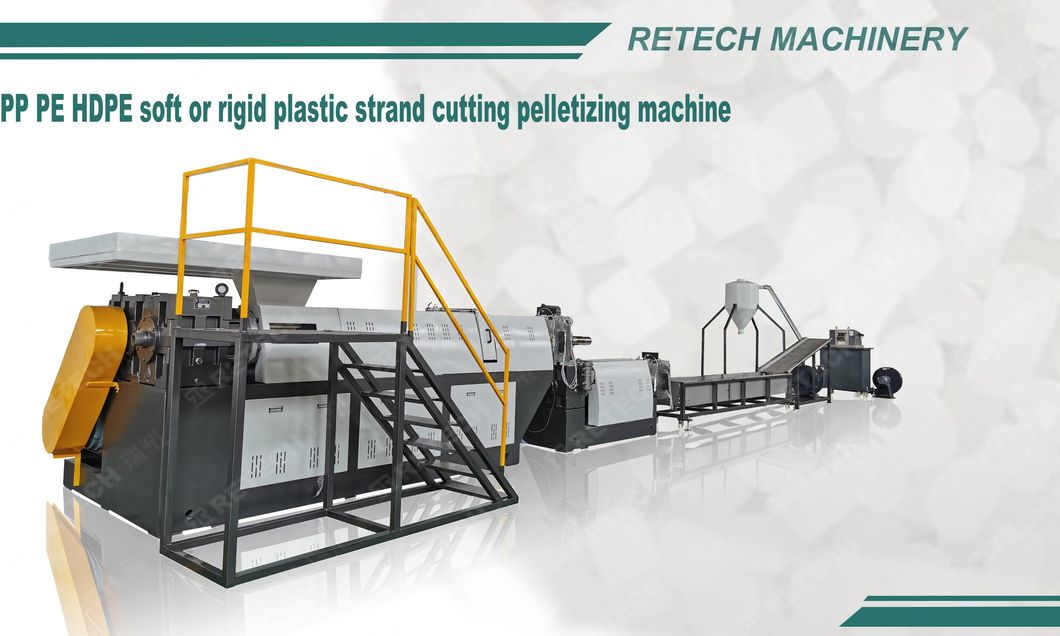

Plastic PP PE HDPE LDPE Film Squeezing Dewatering Strand Pelletizing Machine

Plastic PP PE HDPE LDPE Film Squeezing Dewatering strand Pelletizing MachineOur machinePlastic PP PE HDPE LDPE Film Squeezing Dewatering strand Pelletizing Machine is the recycling machine which make the plastic into pellets. RETECH series compacting pelletizing system, it is a strand cutting type m......

Send Inquiry

Product Description

Plastic PP PE HDPE LDPE Film Squeezing Dewatering strand Pelletizing Machine is the recycling machine which make the plastic into pellets. RETECH series compacting pelletizing system, it is a strand cutting type machine designed for low density plastic articles. It could provide the excellent re-pelletizing and recycling solution for film, raffia, filament, woven bag and nonwoven fabric and other consumed / post soft or rigid plastic. Our pellet making machine has a wide application in PE, PP, CPP, BOPP, PS, PPS, EPS, ABS, PA, PLA, PET waste plastic materials recycling field.

| Type | RM80 | RM100 | RM120 | RM140 | RM160 | RM180 | |

| Capacity(kg/h) | 150-250 | 300-420 | 400-600 | 600-750 | 800-950 | 1000-1200 | |

| Energy consumption(kWh/kg) | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | |

| Length(mm) | 10,300 | 10,300 | 11,400 | 11,400 | 14,800 | 14,800 | |

| Width(mm) | 6,200 | 6,200 | 6,450 | 6,450 | 6,850 | 6,850 | |

| Height(mm) | 3,500 | 3,750 | 3,980 | 4,250 | 4,460 | 4,850 | |

Compactor | Volume(L) | 300 | 500 | 800 | 1000 | 1200 | 1400 |

| Motor Power(kw) | 37-45 | 55-75 | 75-90 | 90-132 | 132-160 | 160-185 | |

Extruder | Screw Diameter(mm) | φ80 | φ100 | φ120 | φ140 | φ160 | φ180 |

| L/D | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | 30-40 | |

| Motor power(kw) | 55-75 | 90-110 | 132-160 | 160-200 | 250-315 | 315-355 | |

Filter (options) | Two position piston type | ○ | ○ | ○ | ○ | ○ | ○ |

| Back flush piston type | ○ | ○ | ○ | ○ | ○ | ○ | |

| Automatic selfcleaning type | ○ | ○ | ○ | ○ | ○ | ○ | |

2nd Extruder (optional) | Screw Diameter(mm) | φ100 | φ120 | φ150 | φ150 | φ180 | φ200 |

| L/D | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | 10-18 | |

| Motor power(kw) | 37-45 | 45-55 | 55-75 | 75-90 | 90-110 | 110-160 | |

Downstream(options) | Strand pelletizer | ○ | ○ | ○ | ○ | ○ | ○ |

| Automatic strand pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

| Underwater pelletizer | ○ | ○ | ○ | ○ | ○ | ○ | |

High efficiency barrel and screw used for extruder with excellent plasticizing result and high output capacity. Adopt high wear resistant alloy material to ensure 1.5 times service life of normal one. Force double vacuum degassing system to get rid of the low molecular, moisture and printing ink effectively, make sure high quality output pellets. High efficiency infrared heater can heat rapidly with continuous thermal insulation, more than 30% energy consumption can be saved than normal heater. Diversified L/D ratio optional for different application. Multi-vacuum degassing system and double stage extrusion system help you solve the problem of recycling heavy contaminated polymer.

A regular single-plate/ piston double-station screen changer or non-stop double-plate/ piston four-station can be installed on head of extruder to present significant filtration performance. the requirements on the filter echnology depend heavily on the quality of the input material as well as the planned use of granules.

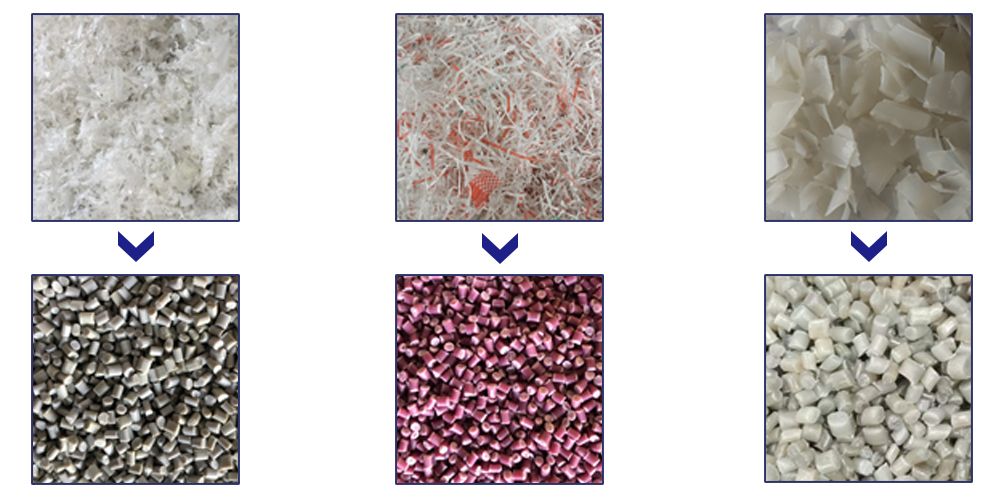

Noodling cutting syatem is suitable to the plastic with MFI degree less than 7, such as LDPE film, PP woven bags, PP jumbo bags, etc. The uniformity, gloss and properties of final pellets can be ensured, round and long shape with diameter of 3-5mm.

Cutting the noodling type into small pellets.

Choosing the proper sizes' pellets.

Collecting the pellets, then put into the proper packages.

Controlling the all machines working and stopping.Which has safty system to protect the machines.

1.Parts which contact material use SUS304 stainless steel, thickness more than 3mm, ensure long service lift time and no second pollution to flakes.

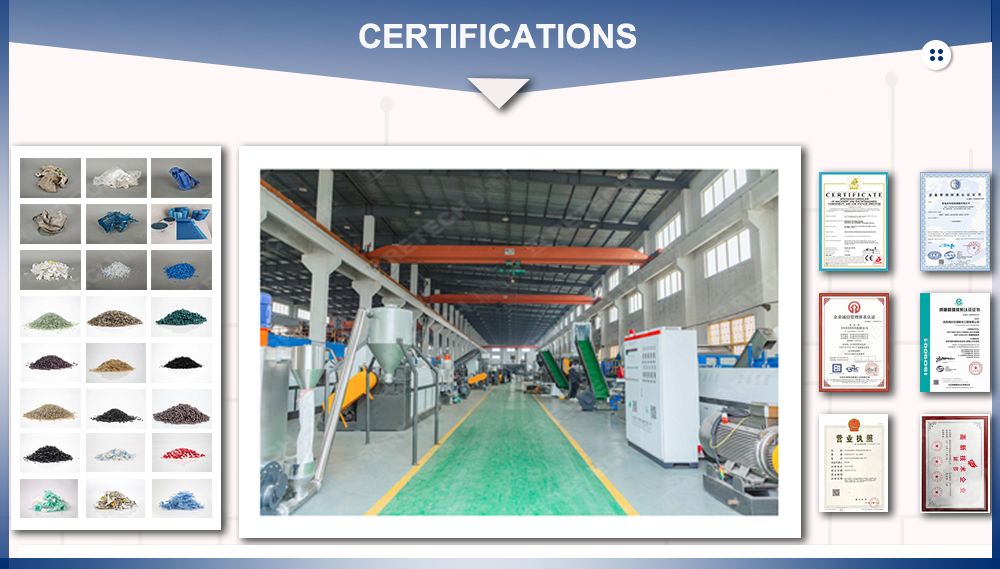

2.World famous brand components applied on the production line- NSK bearing, Siemens contactor, Omron temperature, FUJI inverter, Siemens PLC control etc.

3. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

4.The whole production equipment is researched, design and manufactured by our company with CE certification, ISO9001 certification; it can be designed based on the dirty flakes, and make sure of the quality of the final products.

Service Before Sale

1. 24 hours online. Your inquiry will be quick reply by email.

Also can go through all questions with you by any online chatting tools (Wechat, Whatsapp, Skype, Viber, QQ, TradeManager )

2. Professionally and patiently introduction, details pictures and working video to show machine

Service On Sale

1. Test every machine and inspect the machine seriously.

2. Send the machine picture which you order, then packing it with standard export wooden box after you confirm the machine is ok.

3. Delivery: If ship by sea .after delivery to seaport. Will tell you the shipping time and arrival time. Finally, send all original documents to you by Express For Free. If delivery it by Express to your door (DHL, TNT, Fedex, etc) or by air to your airport, Or logistic to the warehouse which you request. We will tell you the tracking number after delivery.

Service After Sale

1. Free insurance for goods

2. 24 hours online to solve any problem. Supply you English manual book and technical support, maintain and install video to help you solve the problem, or dispatch worker to your factory.